Cement Powder Trailer

The discharge port of the powder tank is also designed to be enlarged, which can ensure that the material can be adequately supplied during unloading, and the material can be discharged at the fastest speed, and the reinforced support of the discharge pipeline, using the principle of triangular stability, can ensure During the unloading process, the pipeline has no displacement, and the stability is the best.

Our cement powder trailers are manufactured with domestic advanced technology, novel design, strong and durable. The cement semi-trailer mainly uses the power of its own engine, drives the on-board air compressor through the power take-off, and sends the compressed air into the air chamber at the lower part of the sealed tank through the pipeline, so that the cement on the fluidized bed can be suspended into a fluid state. Our air bag type has large bearing capacity, fast unloading speed and small residual amount, which can quickly complete the unloading work.

Details Of Cement Powder Trailer

The fluidized bed in the bulker cement tanker is scientifically designed and reasonably arranged, which can effectively shorten the unloading time, improve the volume utilization rate of the tank body, and reduce the residual ash rate, which is 0.2%. The tank body adopts a double-cone incline horizontal structure, double-pipe air intake and double-cylinder feeding, and its discharge speed and residual rate have also exceeded the standard requirements in the industry.

Cement Powder Trailer Specifications

Brake system | Dual Line braking system |

Emergency valve | WABCO |

Brake air chamber | Six big double air chambers |

Electrical system | 1. Voltage: 24v 2. Receptacle: 7 ways (7 wire harness) |

Tail lamp with turn signal, brake light & reflector, side lamp etc. | |

One set 6-core standard Cable. |

The Working Principle Of The Cement Powder Trailer

the energy of the powder particles is transmitted to the air compressor through the action components such as the power take-off and the transmission shaft, and the compressed air flows into the tank body through the compressed air, and the powdery substance is liquefied through the liquefaction equipment. The pressure difference inside and outside the body sends the powdery substance and gas to the designated place through the unloading line.

Our Service

1.Has been exported to more than 40 countries, with good after-sales service

2. Strong load capacity

3. Chengda has its own factory, 2-axis and 3-axis optional, can be customized

4. Considering the road conditions, manufacture the most durable tankers, especially for the African market. Can be well adapted to complex road conditions

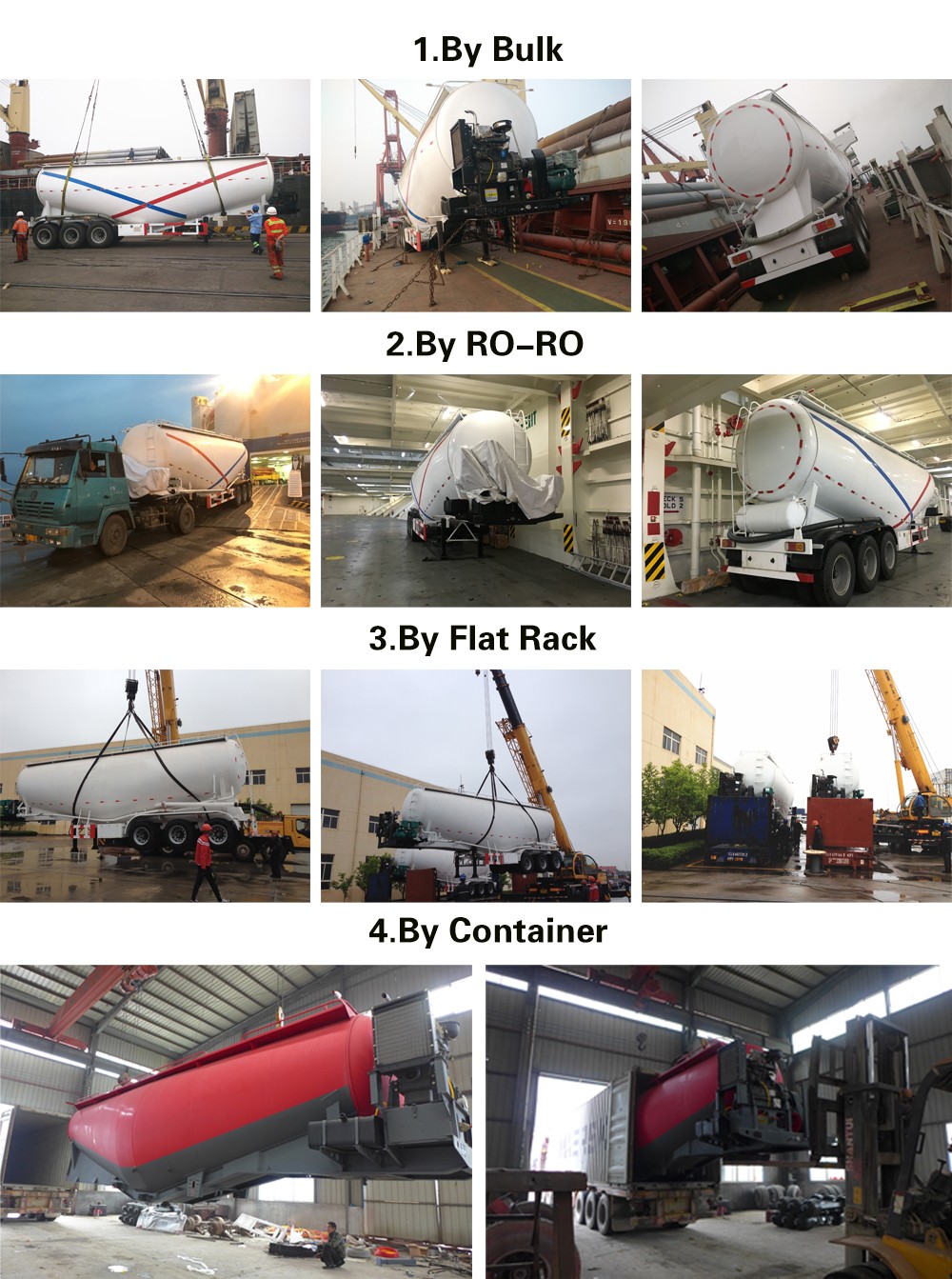

Sea Transportation

Cement semi-trailers are transported by roll-on, bulk, 40 flat racks.

We will choose the most suitable, cheapest and safest way for you. We cooperate with many shipping companies. You can also put forward your idea, we will transport it reasonably according to your idea, we will wax the surface before transporting the cement semi-trailer to avoid rust, if necessary, we will put a car cover on it, also Rust can be avoided.

Submitted successfully

We will contact you as soon as possible